SERVICES

Product Improvement, Problem Solving

Product Research & Development Support

Concept development

Literature & standards reviews

Preliminary design

Material characterization

Material selection

Process selection

Prototype testing

Root Cause Failure Analysis

Failed product inspection

Laboratory examination

Microscopy/Fractography

Non-destructive testing (NDT)

Forensic investigation

Manufacturing troubleshooting & support

Strength & Life Assessment

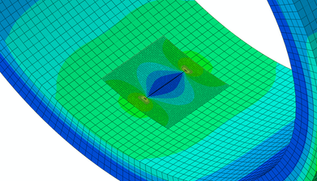

Stress analysis

Finite element analysis (FEA)

Laminated plate & beam analysis

Environmental stress cracking (ESC)Environmental aging

Fatigue, Creep

Other Capabilities

We are partnered with a number of shops, laboratories, and other service providers to offer complete solutions:

Computer Aided Design (CAD)

Machining & Fabrication

FEA Software (Abaqus, 3DExperience)

3D Scanning, CMM

Mold Design & Manufacturing

Prototype Manufacturing & Testing

Metallurgical and Materials Labs

Microscopy, SEM

Analytical/Chemistry Analyses

Mechanical Property Testing

Strain Gauging and Other Instrumentation

Multi-Party Inspection Facilities

Accelerated Environmental Aging

EXPERIENCE

Snapshots

ABOUT US

Meet Dr. Hayes

Dr. Michael Hayes is a licensed Professional Engineer, specializing in solving problems at the intersection of mechanical engineering and materials science. During his 20+ year career, he has worked in a wide range of industries and applications, including consumer products, automotive, civil infrastructure, medical devices, & recreational products. He started his career at Michelin Americas R&D Corporation in 1998 as a Materials Researcher in textiles and rubber compounds for tires.

After completing his Doctorate, Dr. Hayes began his consulting career at Stress Engineering Services, Inc. in 2004, assisting manufacturers in product design, performance, & failure prediction. He then transitioned to failure analysis & forensic engineering, joining Engineering Systems Inc. (ESi) in 2007 as a founding member of their Atlanta, GA office. During his 10+ years at ESi, he led or participated in numerous multi-disciplinary investigations and served as an expert witness in product liability cases and insurance claims. During this time, he also co-authored "Fractography in Failure Analysis of Polymers", a Plastics Design Library publication.

In 2017, Dr. Hayes joined ESE Carbon, a startup manufacturer of one-piece carbon fiber composite wheels. Initially, he developed the company's wheel design methodology and built out their material property database, working with independent labs and Oak Ridge National Laboratory (ORNL). He served as the in-house authority for mechanics and materials related issues, including micro-mechanics models, laminate theory, stress analysis, finite element analysis, composite failure models, and damage theories. Then, as the Head of Product Development, Dr. Hayes managed laboratory and proving grounds testing and postmortem analysis of prototype wheels, introducing non-destructive test (NDT) methods to assess manufacturing quality and diagnose failure modes. He also provided support to Manufacturing to address process-related problems in lay-up, tool closure, infusion, cure, post-curing, coatings, and ancillary metallic mounting hardware. As Vice President, Head of Engineering, Dr. Hayes worked with the CEO and Business Development to interface with clients and investors. He notably served on the SAE taskforce to develop SAE J3204 "Aftermarket Composite Wheels...Test Procedures and Performance Requirements". He continues to sit on the SAE Wheel Committee and serves as a reviewer for various scientific journals. He is a co-inventor of the "E2" and "E3" wheels, a commercial truck wheel, and a 2-piece wheel for military ground vehicles -- all carbon fiber/epoxy composites.

In his personal time, Dr. Hayes enjoys spending time with his family and relaxing at the lake. He is an avid tennis player, skier, spy novel junkie, and car enthusiast.